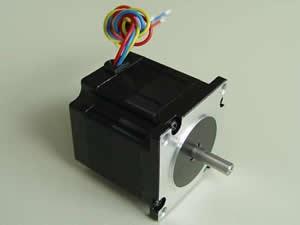

Hybrid Stepper Motor

1. Product Introduction

The hybrid stepper motor is an open-loop or closed-loop control system that converts electric pulse signal into angular or linear displacement. The amount of angular displacement is controlled by regulating the number of pulse, thus achieving accurate positioning.

Integrating the advantages of permanent magnet type and variable reluctance type of product, the hybrid type product features large output torque, good dynamic performance and small step angle, but its structure is complex and its cost is relatively high. It is widely used in the medical equipment, office automation field, industrial automation field (like textile machinery, packaging machine, mechanical arm, etc.)

This device is composed of stator, rotor, end cap and other parts. Its stator has multiphase winding and the rotor adopts permanent magnet material. Both the stator and the rotor have multiple teeth to improve the stepping accuracy.

According to the winding on the stator, hybrid stepping motors are divided into two-phase type, three-phase type, five-phase, etc. The most popular type is the two-phase one. It accounts for more than 97% of the market share. This is because it is cost-effective. After matching a subdivision driver, the effect is better.

The step angle of the two-phase hybrid stepper motor is 1.8°. Accompanied by a half-step drive, the step angle is reduced to 0.9°. Equipped with a subdivision driver, the step angle can decrease by 256 times, reaching about 0.007°. However, due to friction, manufacturing precision and other reasons, the actual control accuracy is slightly lower. Different subdivision drivers can be equipped to change the accuracy and effectiveness.

2. Certification

Our company has obtained the TS16949 certification and our product is certified by CE and RoHS. We can also apply for UL certification according to customers' needs.

3. Optional Accessories

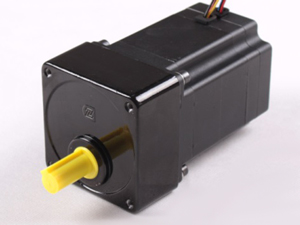

The motor can be equipped with a gearbox, encoder, brake, external drive, or built-in drive. Pulley or gear can be installed in the output shaft. Connectors can be installed for the leads. The shape, length and diameter of the shaft as well as the length and color of the lead can be designed according to the requirements of customers.

4. Notes

A. Before installing this product, be sure to use the spigot of the front end cap for positioning. In the meantime, pay attention to tolerance matching. Make sure that the motor shaft and load shaft are strictly concentric. Decentration will cause the shaft to break.

B. When this device is connected with a load, knocking is strictly prohibited. Because knocking the shaft and bearings may affect motor performance, or even damage it.

C. Please do not wrongly connect the phase of the motor and the drive. When wrong phase or phase loss occurs, the motor can not operate normally and the drive may be damaged.

5. Remarks

A. We can design and produce products according to the requirements of customers.

B. Our products are distinguished according to the base size. For products with the same size of base, they are distinguished by the body length or electrical parameter.

C. We provide an 18-month warranty for our products.

Related Names

Step Electromechanical Device | Hybrid Stepping Motor | Stepper Motor with Hybrid Type | Hybrid Induction Motor

Changzhou Fulling Motor Co., Ltd.